Accessories

Earth Rammer

Uneven landscapes are a nightmare for any landscaper. If you are in the business of landscaping and laying paving tiles, a levelled surface is a requirement you cannot avoid. Usha Rubbers understands your concerns and has come up with the Earth Rammer. This machine helps you level any surface effectively. The Earth Rammer by Usha comes with a greaves diesel engine, blending power output with portability. Using an Earth Rammer to prepare the land for paver laying is one of the crucial steps that ensure the quality of landscaping endeavours. The wet cast concrete paving blocks require a levelled surface so as to offer ideal aesthetic and functional qualities. Interlocking concrete paver blocks and interlocking tiles function their best when the surface on which they are laid are prepared carefully, removing any lose debris and compressing the ground underneath before the laying of chips. This is the ideal way to manufacture interlocking paver blocks and the Earth Rammer by Usha helps with this greatly.

SPECIALITIES |

|

| Compacting Capacity | 3 to 5 Times |

| Centrifugal Force | 1300 Kg |

| Eccentric Movement | 52.5 N/Cm |

| Frequency Of Vibration | 50Hz (Max) @ 300 RPM |

| Moving Speed | 20 m/Min (Max) |

| Gradient | 25% (Max) |

| Compacting Plate Size | 500x600x16mm |

| Direction Of Travel | Forward |

| Weight | 180Kg.(Approx.) |

| Prime Motor | 5 HP Greaves Air Cooled ROBO Diesel Engine |

| Model Code | ER-01 |

|

|

Accesories & Spares Electric Motor Variant Available Spare Diesel Motor/Spare Electric Motor Available On Request |

|

||

|

||

|

Accesories & Spares Electric Motor Variant Available Spare Diesel Motor/Spare Electric Motor Available On Request |

Paver Cutter

While designer flooring tiles and concrete cabros are a miracle of tessellation engineering, the patterned beauty of these patterned concrete blocks and patio stones are best experienced when their beauty is not disturbed. Unfortunately, all landscapes do not follow the same outline and in these cases, there is a requirement for cutting the concrete pavers as per requirement. Usha Rubbers introduces HULK Paver Cutter. Made with state of the art technology, HULK is an example of the pure engineering genius that Usha endorses and follows. The easy to use machine is able to accurate cut the concrete paver blocks without causing any damage to its surrounding regions. This means getting the exact require shape for every situation in your landscaping needs.

SPECIALITIES |

|

| Mild Steel / PU Wheels | |

| Height Adjustable For 60mm / 80mm Pavers | |

| High Leverage Handle | |

| Model Code | CC-01 |

Rubber Gloves

The interlock paver brick design industry is one of the largest areas of auxiliary construction industry in the world. This means that it employs a large number of people and due to the limitations of automation technology, a good chunk of the processing is still economically viable only through manual labour. Therefore it is in the interest of players entering into the concrete paver block industry to ensure the safety of those who are hired to perform manual labour. Usha Rubbers prides itself in procuring the best quality industry grade Rubber Gloves for use in the vibroform parking tiles manufacturing industry. Safety regulations the world over require that employee safety is the number one priority and we at Usha Rubbers agree. The use of materials such as cement, gravel and other chemicals including the oxides and hardeners require the use of Premium Quality Rubber gloves.

Trolleys

A few things are a requirement for any industry to succeed. The right attitude, the right people, the right setting and of course, the right tools. Usha Rubbers brings to you a wide range of trolleys to be used in paver block designer floor tile manufacturing process. The trolleys come equipped with high quality parts as well as the best engineered design to increase manufacturing speeds. Wet cast concrete pavers require the right mix of ingredients to be mixed readily. The trolley range of products from Usha Rubbers ensures that you get your money’s worth by helping you to get the right concrete paving blocks manufactured perfectly.

SPECIALITIES |

|

| 4-Wheeler Trolley | |

| 5 x 3 Brick Shifting Trolley | |

| 4 Auto Retreaded Tyres With Heavy Bearing | |

| Model Code | TR-01 |

SPECIALITIES |

|

| 2-Wheeled Trolley | |

| Concrete Trolley | |

| 2 Auto Retreaded Tyres With Heavy Bearing | |

| Model Code | TR-02 |

SPECIALITIES |

|

| Single Wheeled Trolley | |

| Concrete Trolley | |

| 1 Auto Retreaded Tyre With Heavy Bearing | |

| Model Code | TR-03 |

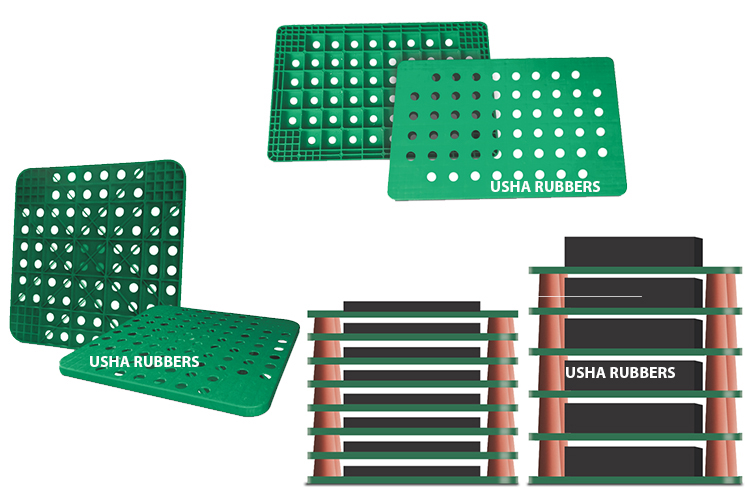

Plastic Bush / Spacers

Mould stacking is a process that is fundamental to attain effective efficiency in concrete paving block manufacturing. The right setting atmosphere and environment is a prerequisite for the successful manufacturing process. For rubber moulds for Paver blocks and for plastic moulds for parking tiles manufacturing, the ideal stacking method is to use the mould stacking trays manufactured by Usha Rubbers. If this method is not possible then the next best method is to use Mould Spacer Bushes. These bushes are manufactured with the best quality materials that helps with its dimensional stability to ensure that it withstands great pressure and does not undergo any deformity. Using spacer bushes ensures that no load is transferred into the inner surface of the filled in moulds, leading you to get the best product on the 1000th use. Spacer bushes also ensure that there is adequate room for water to escape as vapours during the complicated setting process.

Stacking Tray

INCREASES THE LIFE OF PLASTIC MOULDS

CAN BE USED ON BOTH RUBBER MOULD AND PLASTIC MOULD

REDUCES THE CURING TIME

INCREASES AIR CIRCULATION

RETAIN THE STRUCTURE EVEN AFTER LONG USE

WIDE BASE, ANTI-FALL SPACERS FOR IMPROVED STABILITY SOLD SEPERATELY

PLASTIC SPACERS AVAILABLE

25MM FOR TILES AND 60MM FOR PAVERS

One of the greatest achievements of the concrete cabros industry is its ability to produce so many concrete tiles without having to invest heavily in real estate. A key feature of the cement parking tiles is that in construction, they can be stacked on top of one another very easily. The older method to go about this included construction of metal racks to hold wet cast concrete blocks or even using marine plywood planks to stack the interlocking bricks on top of each other. Both of these methods are cost and time consuming. Usha Rubbers has come up with the best solution for this situation and that is the use of our proprietary stacking tray designs.

Made with Reinforced Crosslink Bond Technology (RCB), these mould stacking trays have achieved the impossible: they are lightweight and have the dimensional stability to withstand heavy duty use. The mould stacking trays by Usha Rubbers are an added advantage to increase the efficiency of the concrete paver tile process. The paving blocks designs are best recreated using a stable setting process that is greatly aided by the Stacking Trays manufactured Exclusively by Usha Rubbers.